Information

Our parts experts are familiar with the construction details of your machine and the coil welding process.

Even when there are no drawings, our team can work out the specifications of your seam welding machine on location.

Our coil welder repair services will ensure that you receive the highest quality welding machine parts and accessories made specifically for your system: We never just duplicate existing parts. MeltingTogether experts analyze wear and tear and damage. Defects may be caused by components other than the part itself, which can have serious consequences for other functionalities within the coil welding process. If necessary, our welding equipment repair service will organize ultra-fast delivery.

MeltingTogether can also organize keeping stock of wear parts (for example welding wheels) for your coil welder. This service provides you with:

- High quality coil welder repair parts

- Fast delivery

- Low stock costs

Below you find a list of parts that we can provide. If a part of your coil joining welder is not mentioned, please contact us to see how we can help you out.

Cases

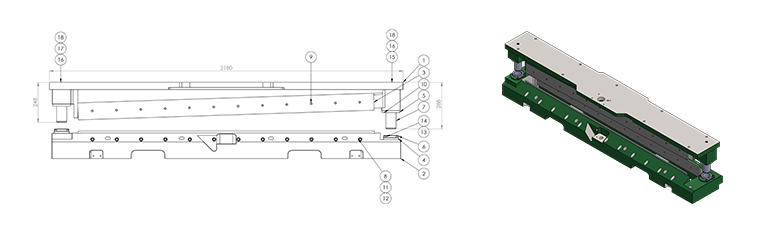

Double Cut Shear

Delivery of new double cut shear unit:

- 1. Customer was facing problems with the quality of his weld. This was caused by the condition of the double cut shear.

- 2. The frame of the double cut shear was worn out and corroded

- 3. The shear knives where filled out with shims. Therefore the lifetime of the shear knives was shorter and this caused the shear making burrs in the metal.

- 1. Since there was no spare double cut shear available, we advised to make a new double cut shear.

- 2. We made a new engineering of the double cut shear. Important in our engineering is the tolerance of the knives (how thinner the material how more critical this is). This made it easier to change the shear in the line.

- 3. After testing in our special test frame, we installed the new double cut shear in the line and overhauled the shear we removed.

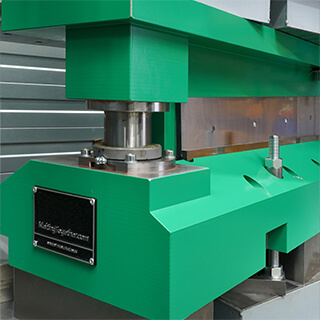

Profiling machine

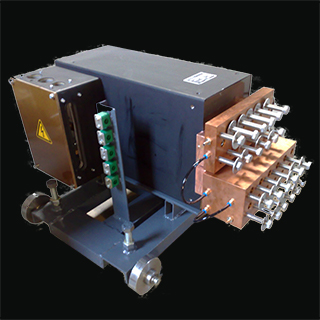

New profiling machine for welding machines.

- 1. The weld wheels were dressed in the coil welder. This causes pollution of copper chips in the line, which leads to insulation problems that influence the weld.

- 2. Customer wanted to profile his welding wheels outside the line with tooling that ensures the quality of the weld.

- 1. Engineering and building a new profiling machine dedicated to the welding wheel of the customer.

- 2. Important is to dress the right shape of the welding wheel. For this purpose, a stable machine (no vibrations), no height oscillations in the weld wheel, and the right cutting tool are essential. If the welding wheel does not have the right form, it influences your overlap and therefore your weld.

Are you looking

for the most satisfactory services for welding machine parts?

Look no further than MeltingTogether.

We can deliver welding machine parts according to your drawings of the coil welding machine, but sometimes drawings of the welding machines are missing, parts are no longer available and full refurbishment might be needed. That’s why when we notice drawings are outdated, we check over the tolerance and material used. We will advise you about possible changes that we think might improve the machine’s quality or make it cheaper to run.

That’s how we differ from other businesses: we can not only provide welding machine parts designed specifically to match your drawings, we can also create drawings for you, test your welding machine parts and offer refurbishing services from our highly qualified and experienced welding specialists.

We provide and innovate parts for coil welders from the top brands: AI Welders, Taylor-Winfield, Miebach, Telemechanique, Guild and others.

You can see our process for reconstructive engineering below.

Our process

Gathering

InformationWe may need to gather additional information from you before working on your enquiry. This might include:

- Drawings

- Specification of requirements (mechanical, electrical, pneumatic, cooling, etc.)

- Reason for changing the welding machine internal part (preventive, problem, innovation, etc.)

Our team of experts will examine your resistance welding machine parts, provide drawings of the problematic elements, and jot down the specifications needed.

Budget

In order to understand how much welding repair service will cost, we first need to examine the product. After providing an inspection we will give a price for making the parts.

We do however aim to always offer a budget price for engineering new coil welder parts. If a price can be agreed on, the customer sends an order to MeltingTogether, where our experts can start repairing and refurbishing the parts of your coil welding machine.

Work

Before starting construction, a final engineering design will be created to showcase the criteria for the refurbishment. Our experts will then build the welding machine replacement parts for your welding machine, as well as additional components if these are needed (this will be agreed with the customer). We will also provide the installation of the welding equipment and its supplies.

We offer repairs at our headquarters in the Netherlands, however, if you are experiencing a complex issue with your machine, and cannot have it transported, we can provide a welding machine repair service at your property.

MeltingTogether has been helping customers with welding machine repairs for more than 20 years. Our international welding specialists are well familiarized with all the intricate details of coil welding machine parts, stipulations, and drawings. We manufacture spare parts that can be used for a wide variety of welding purposes and machines, no matter how old or unique your coiling welding machine parts are.

Once the work has been done on your coil welder parts, MeltingTogether will provide you with a final test report.

The following tests are carried out:

- Visual inspection

- Functional test

At MeltingTogether, our experts create full documentation for the part. Customers are welcome to visit our testing facility to check the parts of their coil welder, but typically this is all done via video to speed up the process. We then move onto shipping your welding equipment and supplies back to you. We offer worldwide shipping.

We do everything we can to keep our partners satisfied. Our processes are fully focused on keeping your systems up and running at all times.

We offer the following coil welder spare parts:

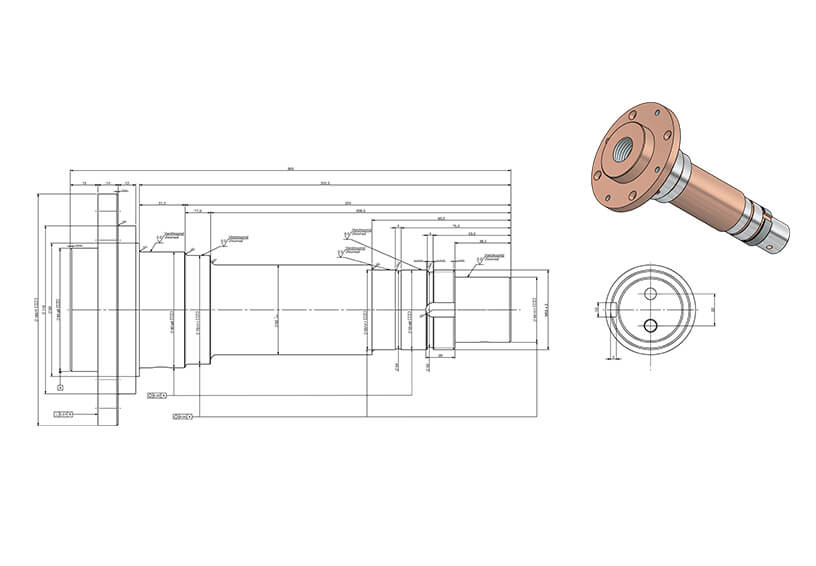

- Welding heads

- Secondary circuit

- Double cut shear

- Overlap clamp

- Pivot clamp

- Carriage drive weld machine

- Cooling and Tooling

- Insulation

- 9. Hydraulic & pneumatic parts

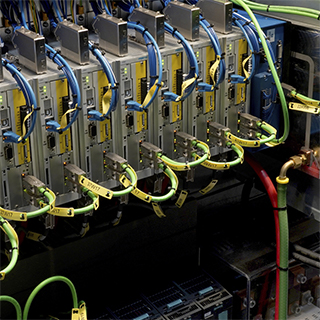

- 10. Electrical wiring

If your required spare parts aren’t available in our list, you can always contact us. We are happy to assist you.

- Drawings

Spare Parts Advice

We want to make a difference, and that’s why we are fully focused on seam welding in the steel industry. We’re not just a vendor; we prefer working with you as our partner. When it comes to delivering parts we go further than the rest: We can even provide stock keeping of your coil welding parts. Together we decide the annual amount of wear parts and the critical spare parts you might need. We can offer you a contract to keep the wear-and-tear spare parts for your coil welding machine in stock. This provides you with the following advantages:

- 100% quality control – we check every welding machine part so that when you need it during a change or breakdown, it’s ready to go

- Quick delivery – because we have it in stock, we can deliver it quickly

- Low stock notifications - we inform you when stock is below an agreed level, and send you an offer so we can replenish stock back to the agreed level.

- Part standardization - Most plants have more than one coil welding line so we try to make as many parts – such as transformers, welding controllers and welding wheels – as similar as possible. That way, we can help you maintain higher quality lines at a lower cost.

- Everything managed by one team – Our experts will help you manage the quality of your parts, servicing, maintenance and the refurbishment of your coil welding machine.

Some welding machine parts and accessories are more critical than others, so we advise to keep the following spare parts in stock at all times:

Weld Heads

All our welding parts and supplies are manufactured using superb quality metal alloys from only the most reliable material suppliers.

Our experts recommend keeping a spare set of weld heads in stock at all times to maintain the efficiency and quality of your coil welding machine. We advise changing the welding head every 12 or 18 months to prevent breakage.

Double Cut Shear

Prior to welding, a good cut is needed on the material you’re welding to ensure a good quality seam weld. When we deliver a double cut shear, we look at the strength of the frame and the blades. This allows for a higher quality double cut shear blade with a longer lifespan.

Weld Controller

Weld controllers don’t often break down, but it’s important to have a spare controller available just in case. Otherwise, you’ll experience a huge number of additional problems.

Transformers

Transformers are similar to weld controllers in the sense that you should probably make sure you have a spare at all times. If your transformer breaks down, you may be waiting 12-16 weeks for a new delivery.

Delivery &

GuaranteesDelivery

All our welding machine replacement parts are ready for dispatch quickly with fast, worldwide delivery available.Guarantees

We aim to provide all our customers with premium quality, resistance welding machine parts, designed precisely to your system requirements. Our policies ensure the high trading quality of efficient and long-lasting parts. That’s why we include a 6-month warranty on our spare parts (normal wear and tear or improper use is not covered).