MeltingTogether can repair and overhaul different types of welding machines and all it’s separate assemblies. We supply parts for welding machines. Below you will find a list of items we repair. If your part is not listed, please contact us and get free advice.

Cases

Welding head repair

Repair of welding head complete with pneumatic gearbox for weld wheel drive.

- 1. Customer faced many problems with breaking of the weld during the production process. This led to extra costs and high downtime.

- 2. The welding process was not stable. While one weld was good, the next weld was poor (too cold).

- 3. Problems came unexpectedly.

- 1. We started an inspection. Checked the drawings and made right tolerances and alignments for the house of the weld head, the shaft and the silver contacts. And we selected the right materials.

- 2. We carried out the mechanical overhaul and tested the welding head and gearbox on our testing facility.

- 3. We installed the welding heads complete with pneumatic gearbox for weld wheel drive and started up production (important is the alignment in the line).

- 4. We have recommended the customer a spare set of weld heads, and changing and overhauling it preventively every 12 or 18 months – to maintain the continuity and quality of the weld.

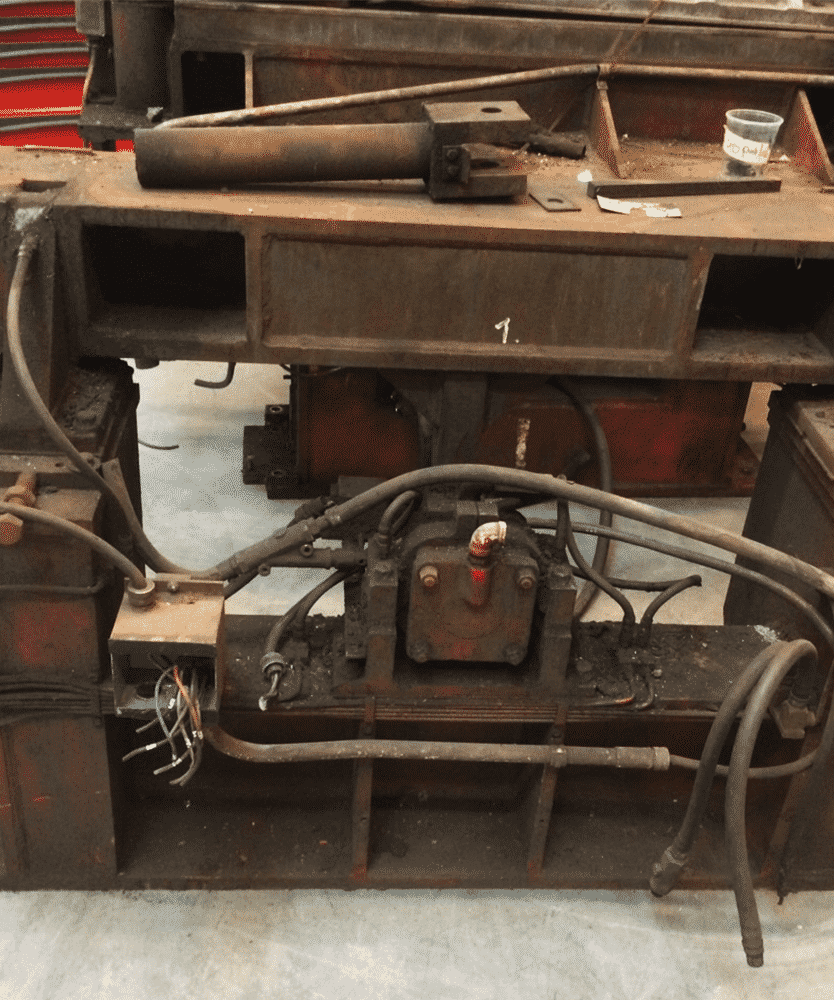

Pivot clamp overhaul

Complete overhaul of the pivot clamp of a Taylor Winfield coil welder

- 1. The guidance was worn out. Because of this, the positioning of the strip was not guaranteed and as a result of this, the welds sometimes broke during the production process.

- 2. The customer didn’t have an equal spare pivot clamp but he had an old pivot clamp of an AI Welder in his warehouse.

- 1. MeltingTogether had the old AI Welder clamp of the customer and made an engineering to rebuild it for there Taylor Winfield coil welder.

- 2. The complete overhaul – Mechanical, electrical, pneumatic, and new grease system was also carried out by MeltingTogether.

- 3. We dismantled the existing clamp from the Taylor Winfield machine and installed in the overhauled clamp.

- 4. Then we overhauled the clamp we took from the Taylor Winfield machine and we installed it in another coil welder of the customer.

Welder Equipment Repair at MeltingTogether

MeltingTogether has been perfecting its services since 1999. We are specialists in welding and overhaul services of resistance coil and drum welding machines.

We focus on the seam welding process and welding equipment repair. You can easily buy welding equipment parts from our MeltingTogether service center, or use our overhaul services to repair your welder equipment safely.

It starts with an enquiry

When a customer sends through an inquiry, MeltingTogether reviews the request and may ask you to provide drawings of your machine, as well as spec requirements (mechanical, electrical, pneumatic, cooling, etc.) We will also need to know the reason for you wanting to overhaul or repair your welding machine.

With this information, we can provide you with a cost for inspection, as well as the price of having any missing drawings made up.

Once a price has been agreed on, the customer will need to send the part or the machine to our testing facility in The Netherlands.

Our Services

Deep inspection

Our deep inspection consists of testing the machine or welding machine internal parts upon arrival at our testing center. Once we have a better understanding of the current status of the machine, we dismantle it for cleaning. We then take measurements of the parts and compare these to the drawings the customer has provided. If there isn’t already a drawing of each part, we will create these.

Inspection report

Within the inspection report, we provide you with the current status of the welding machine, the measurements and pictures upon arrival as well as possible improvements that can be made to the product. We will also create a quote for cost and time it will take for the overhaul to be completed.

The customer is always welcome to visit the testing facility to take a look at the machine and discuss innovation ideas in person with our team. If you are further afield, we of course can always arrange a video call.

Equipment overhauls & repair

We follow a specific overhaul procedure to ensure the weld’s efficiency and effectiveness. Once the customer has reviewed the inspection report, and confirmed how they would like to proceed, the overhaul can begin. The overhaul will be carried out specifically to the previously discussed inspection report. The weld head repair service is performed at our testing facility.

Testing & Surveying

In the last step, MeltingTogether tests the durability of the equipment. Comprehensive testing of the component being weld is done before it can be planted and delivered. In our case, testing and application of the overhauled welding head are made to make sure of the universality of the weld made on the subject welding equipment.

Technical & Product support

There might be some disturbance issues with your welding machine line in other ways, in which a full overhaul is not needed. We can tackle such problems: The typical solution to such issues is the stocking of components: A good stock of components is always recommended to avoid loss of energy and time on an on-going project. We provide you with these stocked parts to help increase your production rate.

Why Should You Specifically Hire MeltingTogether?

When choosing a coil welding specialist, it’s important to look at their working line policies, additional services and features they offer. To help, here’s ours:

Our Services

We provide high-quality welds using the best welding wheels for your coil welding machine and use the most suitable material for an overhaul using these welding wheel parts.

Our international welding specialists team comprises of experts familiar with coil welding machine lines, as well as head welding repair and coil welder overhaul.

We provide all our customers with a recommendation on how much and which stock parts should be held for the coil welder. We also offer the required components and replace these regularly after 12-18 months to avoid the chance of wear and tear. We can provide instructions on stock management and requirements.

All overhauls related to the welding head are carried out using the best equipment, which is continuously innovated. This is to ensure the universality of the part being welded.

We provide welding support to our customers and clients to increase and maximize operational efficiency and durability while keeping the cost and stoppage of equipment to a minimum. A reduced loss of operation is likely expected after our services.

Our features

We are masters and specialists in welding machine repair.

Our expert team will perform the overhaul services, repair the required parts, and upgrade the system to ensure the proper functioning of equipment.

Constant guidance and support from our team is provided.

We will provide high quality, long-lasting parts and can offer overhaul work related to spare parts.

We keep an eye on all forms of cylinder head welding repair, resistance coil welding, and overhauling services associated with the assemblies related to them.