Identity

01

specialize in everything that influences the seam weld

03

are trusted by major steel industry manufacturers that use coil welding machine lines and drum welding machine lines

We

02

have experts in both steel drum machines and coil welding machines

04

overhaul all types of manufactures of coil welding and drum welding machines and their separate assemblies

01

consists of qualified welding specialists with engineering, mechanical, electrical, and programming skills

03

performs overhaul, repairs, and upgrades for different types of welding machines.

Our Team

02

helps you out if you need welding consulting services and welding support

04

delivers high quality welding parts and can manage your spare part process

Identity

We

01

specialize in everything that influences the seam weld

02

have experts in both steel drum machines and coil welding machines

03

are trusted by major steel industry manufacturers that use coil welding machine lines and drum welding machine lines

04

overhaul all types of manufactures of coil welding and drum welding machines and their separate assemblies

Our Team

01

consists of qualified technicians with engineering, mechanical, electrical, and programming skills.

02

helps you out if you need consultancy and support

03

performs overhaul, repairs and upgrades.

04

delivers high quality parts and can manage your spare part process

Services

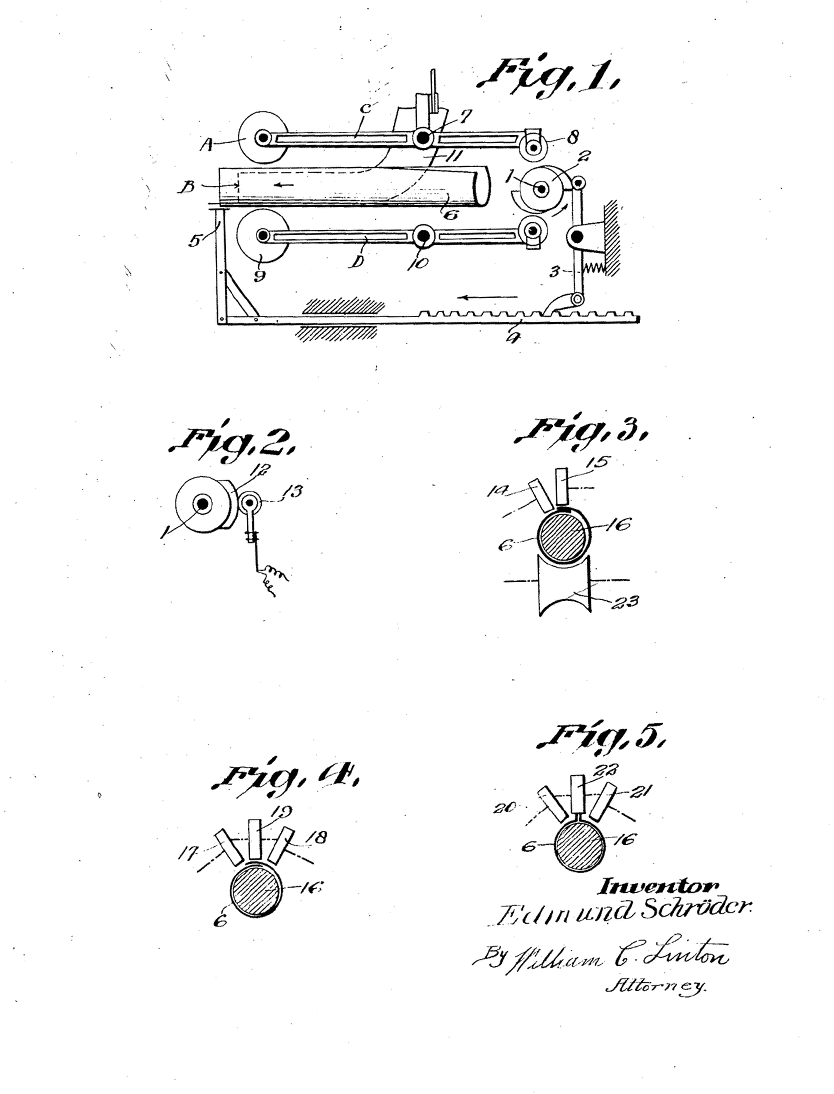

Overhaul

Our processes guarantee high-quality Welding Repair Service that preserve the continuity and functionality of your coil welder or drum welder.

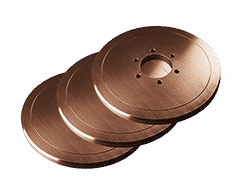

Parts

Premium quality pays off. We only use the finest welding machine parts. Fast worldwide delivery of parts for resistance coil welding machines and resistance drum welding machines.

Consultancy & Support

We combine our expertise and your knowledge of the production process to create high-quality technical solutions for our welding consulting services.

What our customers say

![]()

![]()

![]()

![]()

![]()

Erik Bijnens

Supervisor Mechanical Maintenance Annealing & Pickling Lines APERAM

After a series of problems, because the original machine builder couldn’t give us the quality of services we needed, we started working with MeltingTogether in 2013. Since then, the ‘downtime’ problem of our two resistance seam welding machines has been solved.

MeltingTogether is a great added value for Aperam Genk. Their technological knowledge and the flexibility with which awarded assignments are carried out are of an extremely high level. I hope to work with MeltingTogether for many years to come!

Yann Le Denn

Manager Engineering, Greif

As a world leader in industrial products and services, Greif has a global manufacturing network for the production of steel drums. These drums are used by Greif customers to transport a variety of materials including food-grade and hazardous goods. Therefore, our production equipment and manufacturing processes must meet the highest standards. Since 2004, Greif has been a customer of MeltingTogether for the servicing and maintaining of our welding machines. MeltingTogether is a very dependable supplier, delivering state-of-the-art solutions in steel drum automation, as well as spare parts management and maintenance support.

Johan Pol

Maintenance manager, Tata Steel

To us, MeltingTogether is a strategic partner when it comes to maintenance, service, and innovation of our coil welder.

MeltingTogether has knowledge of seam welding and everything that effects the weld.

As a project team they provided for us a complete overhaul of the overlap clamp during our yearly downtime. At the same time they delivered and build in a new double cut shear and weld controller. All within budget and timelines.