MeltingTogether overhauls any drum welder and their separate assemblies. We also provide parts & equipment for the resistance seam welding machine. Below you can find a list of items that we repair and overhaul. If your part is not listed please contact us to see what we can do for you.

Cases

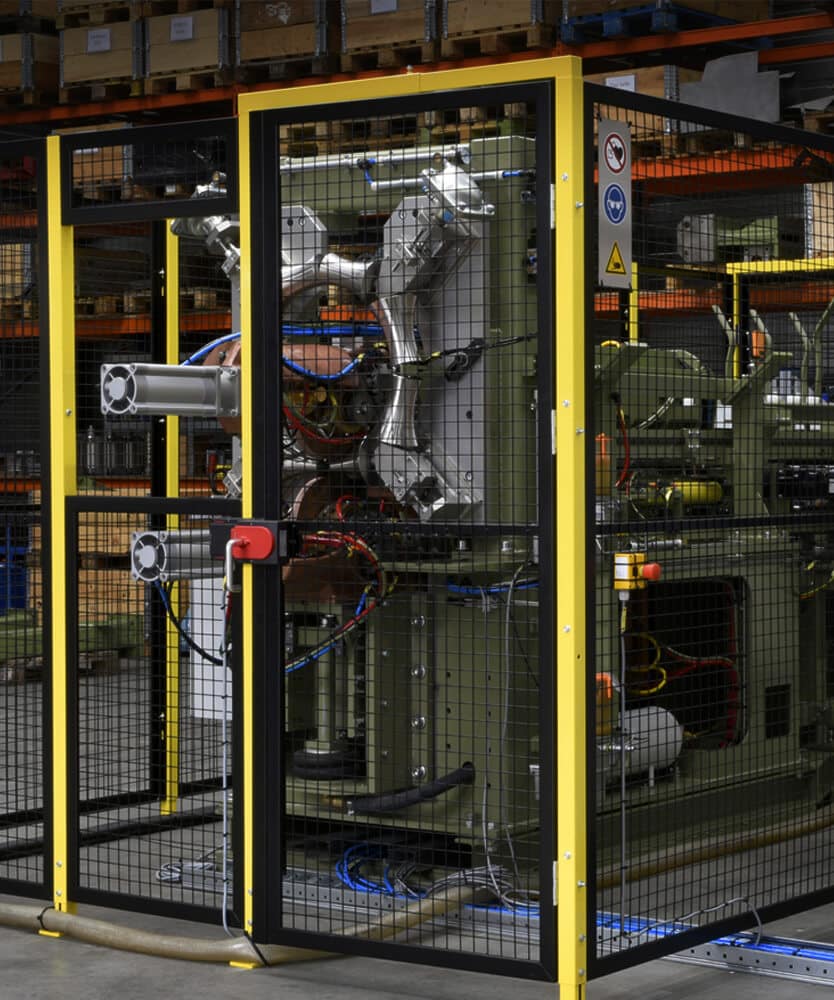

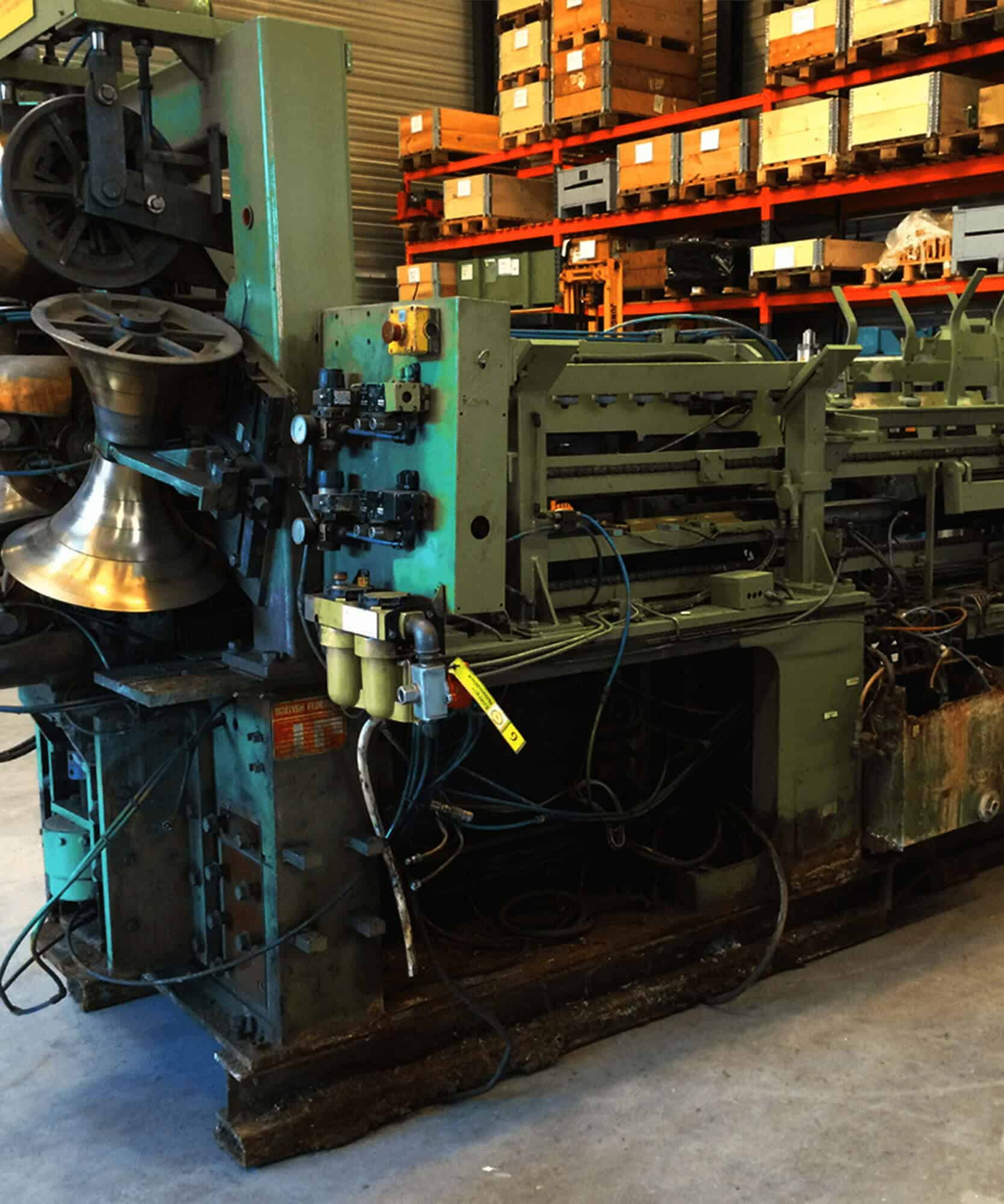

British Federal Welder Overhaul

Complete overhaul of a British Federal Welder for a customer in Egypt.

- 1. The customer had this British Federal Welder in Spain from 1968. The welder was able to produce drums with a inner diameter of 571,5mm and it had to be rebuilt to produce conical drums with an inner diameter of 520mm.

- 2.The machine had among others the following issues: Forming of the sheet from 0.7 was not stable. The weld was not ok, problems with the starting of the weld (insulation problems).

- 1. We provided a complete overhaul on our location in The Netherlands.

- 2. Overhauling all critical parts (forming rolls, pusher, welding heads, ratchet, knurl houses and more).

- 3. Engineered and built completely new hourglass section.

- 4. Designed, build and programmed a whole new electrical-, pneumatic-, grease and cooling installation on the machine.

- 5. Commissioning of the machine, complete with documentation.

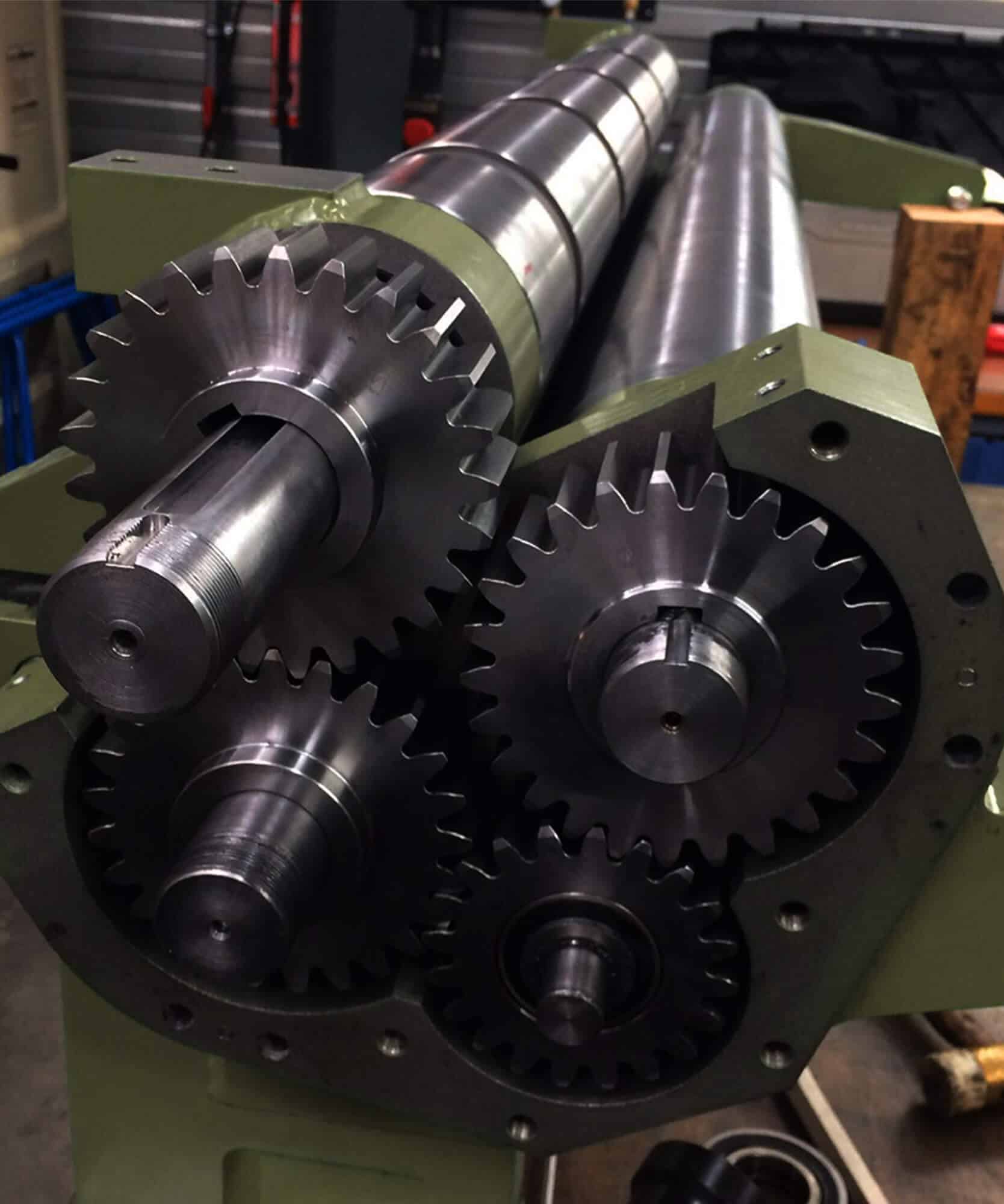

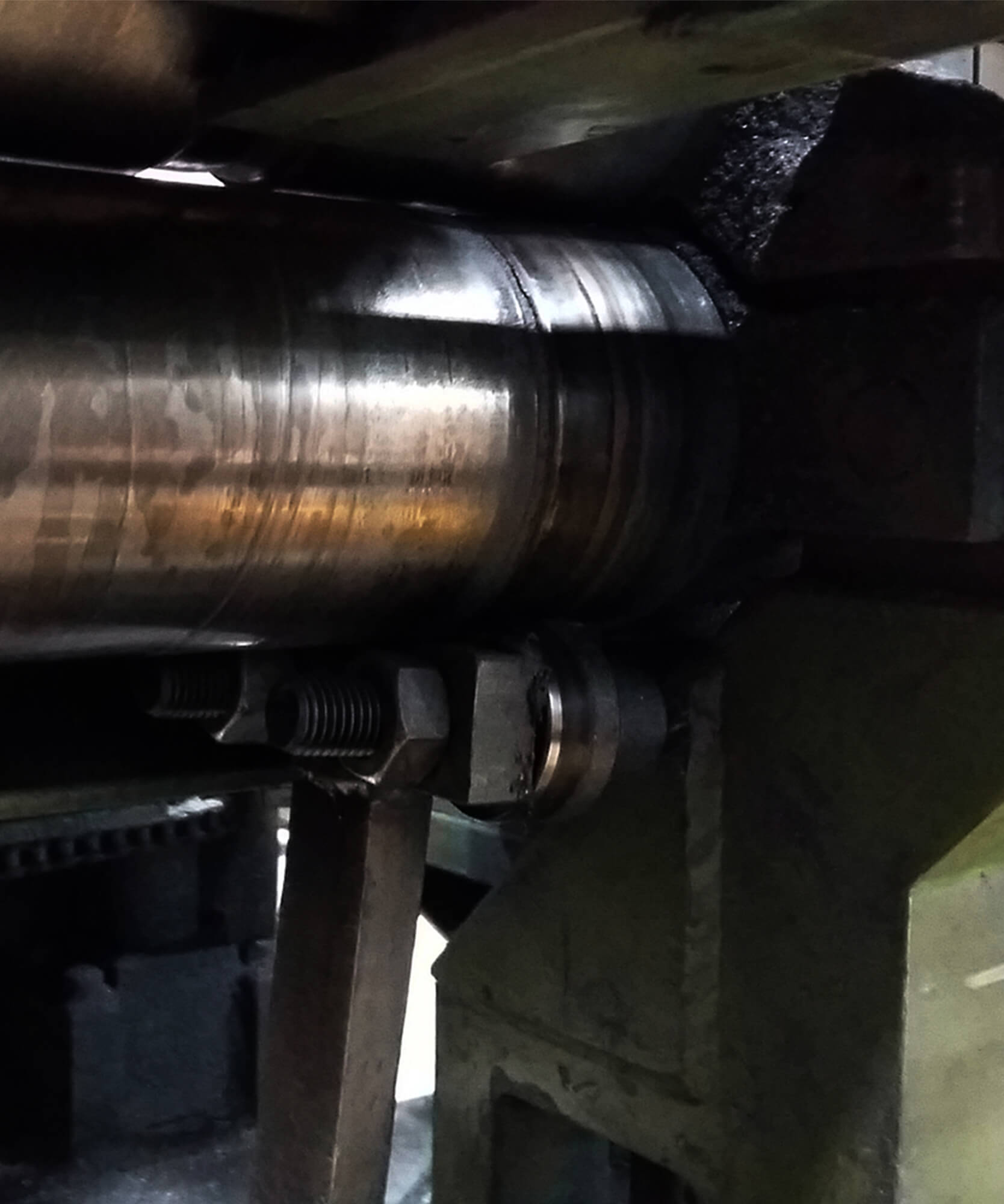

Forming rolls overhaul

Overhaul of the forming roll system for a Newcor welder.

- 1. Customer wished to place his drum welder in another plant and therefore the input direction of the sheet in the forming rolls needed to be changed from left to right.

- 2. Also required mechanical overhaul of the forming rolls.

- 1. New drawings where made to change the infeed direction of the forming rolls.

- 2. After measuring the forming roll system, we noticed that the alignment of the bearings of the upper and lower roll where not in line.

- 3. We installed new components and carried out the overhaul. The alignment of the bearings was repaired. This is very important because otherwise you make a conical body.

Drum Welder Repair

at MeltingTogether

MeltingTogether offers renovation services for both coil and resistance drum welding machines.

We overhaul all types of drum welders and their associated assemblies, so you don’t need to worry if an issue occurs in your drum welder: It is our first and foremost obligation to help you in your time of need.

We offer technical help in drum welding machine overhauls, as well as universal guidance and recommendations for all drum welding machine lines. Our aim is to ensure the best production of your machine lines time and time again.

MeltingTogether is a reliable partner for thorough inspections. We audit the machine line, its components, and parts.

Below is a list of features we overhaul:

Can I overhaul

a drum welding machine myself?

We would not recommend trying to overhaul a resistance drum welder yourself. Taking the matter into your own hands can lead to more problems and costs. To ensure the safety of your machine, and your workers, we suggest hiring a certified welding specialist.

Why choose

MeltingTogether for repairs?

We have a safe, customized strategy to deal with issues relating to your welding machine. We offer fully safeguarded inspections and refurbishment services that work to provide you the best finish.

Our strategy

Inquiry and Deal

- A customer will enquire about overhauling a drum welding head.

We ask customers to provide as much information as possible and to include drawings and dimensions along with the reason for the overhaul. This is so we can understand how to tackle the problem safely and easily. - We then take a complete measurement of the machine’s parts to provide us with the alignment settings we need.

MeltingTogether offers not only physical and technical support, but also the design and production of an electrical, pneumatical system for your weld head drum welder. - We thoroughly investigate whether an overhaul is necessary so that we can avoid direct damage to the barrel welder.

Sometimes, it may be better to fully refurbish the resistance drum welding machine, rather than attempting to overhaul specific components. - A quote for a full, extensive inspection is provided.

- A customer will enquire about overhauling a drum welding head.

The Inspection

Once the customer has agreed on a price for the inspection report, we follow a detailed procedure to find the best way to repair the machine, at the best price.

Our extensive inspection procedure follows the following steps:

- The part or machine is tested to understand its current status on arrival at our facility.

- It is then dismantled and cleaned, before we compare its measurements to the drawings provided.

- If drawings haven’t been provided, we will create these.

- A complete, detailed inspection report is made and sent to the customer.

- The report will feature information regarding the status of the machine or part when it arrived with us.

- The findings of the inspection with measurements and pictures.

- Possible improvements we would recommend.

- We will also provide an estimate price for the repair and how long we predict it will take.

- The inspection report can be provided remotely, or the customer can visit our facility to discuss the report in depth.

- We then send the customer an invoice for the inspection report along with a quote for the repair.

Once you have the quote for the repair, you are more than welcome to shop around. However, we aim to provide all our customers with the best, most reasonable price.

The repair

- When the customer has agreed on the quote and placed the order, the welding machine repair begins.

- A complete refurbishment is provided to the welding head drum machine at our headquarters in the Netherlands based on the previously created inspection report.

- Parts and welding equipment of the refurbished drum welder are dismantled for cleaning and tested using both a visual inspection and functionality test to ensure your machine complies with our testing procedure.

- After the welding repair service, the machine can be collection from our headquarters. If the customer cannot collect, a shipment quote is provided.

- We will provide complete documentation regarding the repair of your drum welder machine for you to keep. This documentation includes a before and after report, no matter if it is the whole machine or simply just a part.

We understand it is tempting to try and fix a problem yourself, however choosing an expert with a clear refurbishment strategy is safer, quicker and easier.